16 Dec

Safety Stock Calculator

While in a business, you won’t be able to afford either running out of stock often or holding too many items in your inventory. Therefore, a business requires maintaining an equilibrium between ordering items at a proper time and keeping the sufficient number of stock as safety stock or buffer inventory. For this, we can use the safety stock formulas to find out a suitable number of inventory required as a safety stock.

However, our safety stock calculator does this for you. Simply enter the maximum and average daily usage of the goods, maximum and average lead time, therefore time taken to get the replacement items.

What is Safety Stock?

Safety stock is the extra number of stock that is kept or say, preserved for emergency uses. To understand simply, safety stock acts as an extra cushion for your business. It adds relief by keeping you safe in the time of fluctuations in demand, or delay in receiving purchase orders.

To understand how a safety stock works, let’s imagine that you have set your reorder point for your low inventory at 10 units. When your inventory falls down, you place a purchase order with the supplier to replenish the inventory again. But what if the transport got delayed or supplier disapproved your purchase order? In such case, if you won’t keep a buffer inventory, you will run out of stock making loses. Therefore, safety stock ensures that you never run out of stock even if contingencies knock your door.

Therefore, safety stock helps you to avoid risks of unforeseen delays and reduces the chances of going out of stock. It preserves your business from delays and variations. Thus, safety stock ensures that you never turn down your customers because of stock unavailability. To calculate the right number of safety stock needed in your business, use our Safety Stock Calculator.

Formula used in Safety Stock Calculator

Our safety Stock Calculator uses the most apt formula to give you the best results. Formula used to calculate the right number of safety stock is,

Safety Stock = (Maximum Daily Usage in Units x Maximum Lead Time in Days) – (Average Daily Usage in Units x Average Lead Time in Units)

Where,

- Max Daily Usage in Units – The maximum number of units that run in a day.

- Average Daily Usage in Units – The average number of units that run in a day.

- Max Lead Time in Days – The maximum time to get your stock replenishment items.

- Average Lead Time in Days – The average time to get your stock replenishment items.

Further, the result will display the number of safety stock that you should keep in inventory to avoid any sales fluctuation.

Example

With this illustrated example, you can easily understand how our safety stock calculator processes.

Find the safety stock using the following informations:

- Maximum Daily Usage = 16 units

- Maximum Lead Time = 24 days

- Average Daily Usage = 8 units

- Average Lead Time = 10 days

The formula to calculate Safety Stock is:

(Maximum Daily Usage in Units x Maximum Lead Time in Days) – (Average Daily Usage in Units x Average Lead Time in Units)

Safety Stock = (16 x 24) – (8 x 10) = 384 – 80 = 304 units

Therefore, the safety stock level is 304 units.

FAQs

Q1. How to determine safety stock in Inventory management?

To calculate the safety stock, simply use the illustrated formula used in our Safety Stock Calculator.

Safety Stock = (Maximum Daily Usage in Units x Maximum Lead Time in Days) – (Average Daily Usage in Units x Average Lead Time in Units)

However, you can directly use our free calculator for better and error-free results.

Q2. What’s the difference between the safety stock and reorder point?

Safety stock is the extra inventory that you preserve to avoid running out of stock because of sales fluctuations or delay. However, reorder point is the number of stock you have set to approve purchase order whenever your inventory level falls. You can use our Safety Stock Calculator to calculate the right quantity to keep in your inventory.

When should I change my safety stock level?

When we say about safety stock level, it often depends on the quantity of products you’re selling. You must check the availability of demand for any new trends, holiday seasons, customer’s purchasing behaviour.

Also, calculate your safety stock for raw materials and finished goods separately. In this way, you will keep the sufficient amount and can acknowledge what amount of safety stock you need to keep in materials as well and can set reorder point efficiently.

Related Tools

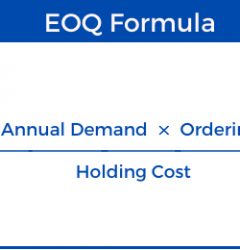

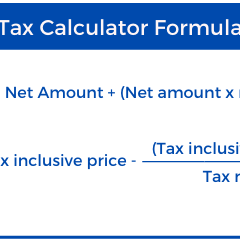

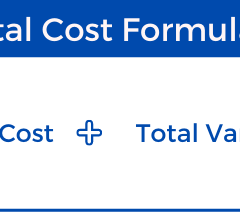

EOQ Calculator | Break-Even Point Calculator | Total Cost Calculator | Profit Margin Calculator